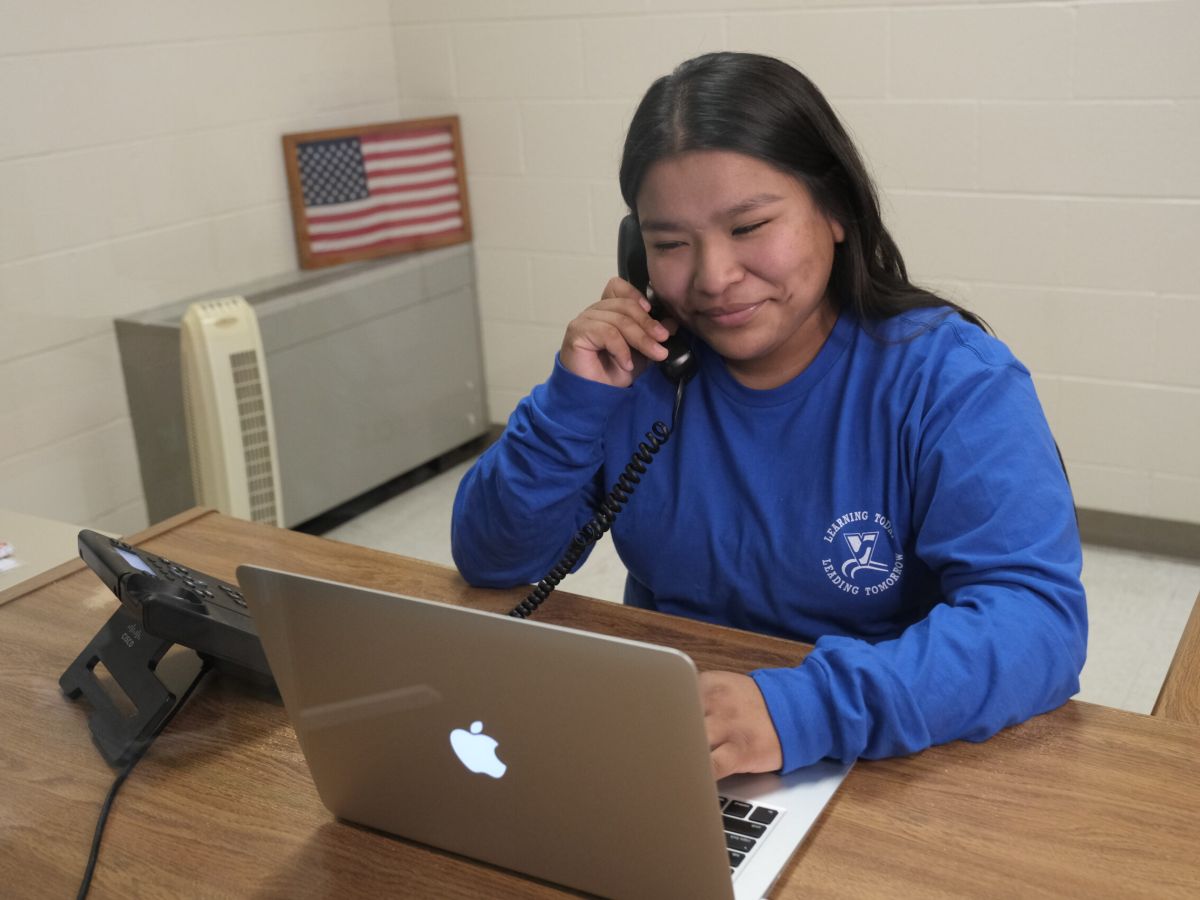

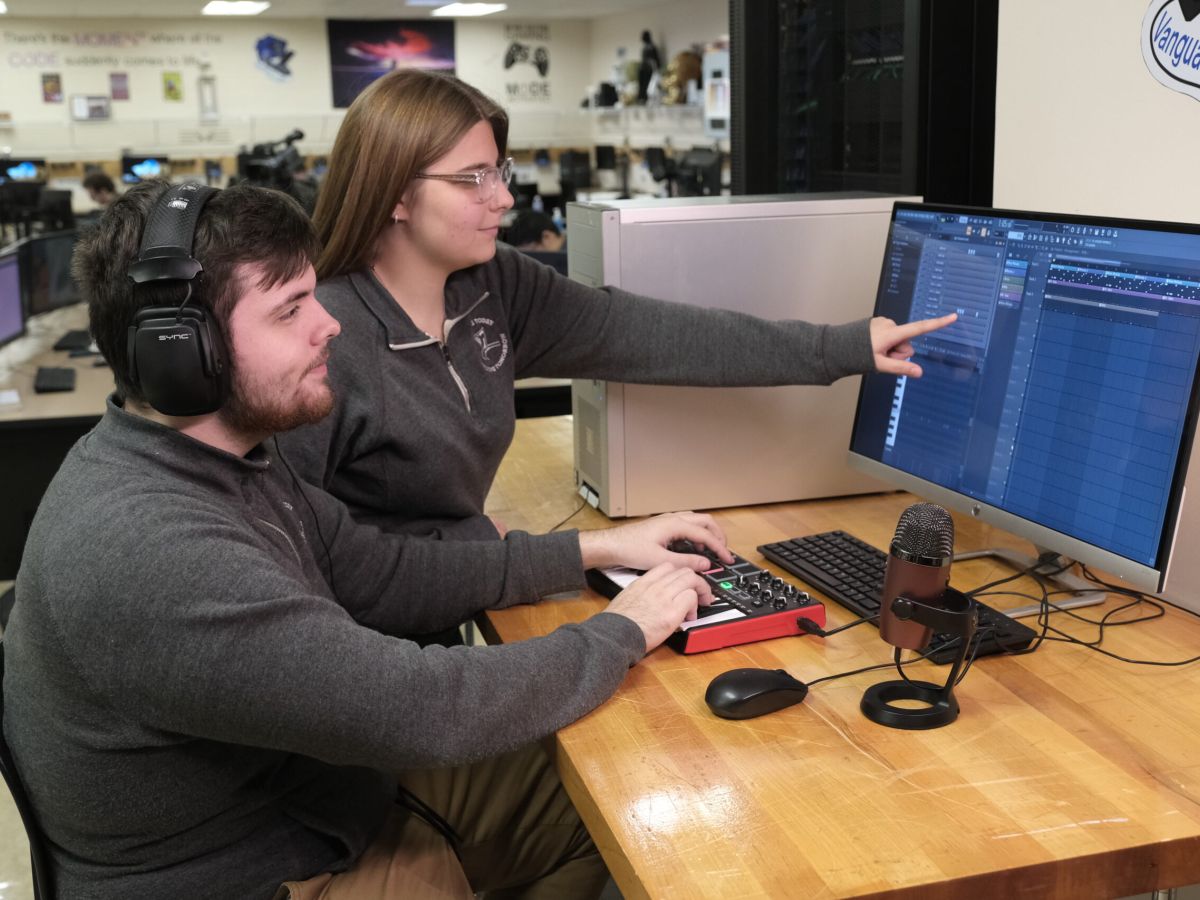

Programs at VSCTC

At Vanguard Sentinel Career & Technology Centers, we are committed to providing a challenging curriculum, skilled instruction, and a learning environment that responds to individual student success. Our work is guided by the belief that every student is capable of attaining high levels of educational achievement in preparation for the future.